Prostheses and Orthoses are a part of the range of assistive technology available to people with disabilities that access rehabilitation services. Any provided device must not only meet a user's current need, but to do so in a manner that allows for the ongoing management of quality. As the organisation providing such services must possess certain general characteristics in order to provide appropriate services and to ensure a climate in which to properly conduct a quality assessment and improvement programme, the requirement of a well-equipped workshop with supportive and optimistic technicians is essential. Hence, our workshop is well-furnished and well-equipped with modern machinaries. All these machinaries are well-maintained and all are upto date. Servicing of all these machinaries is done on a regular basis. All technicians who work in the workshop are supportive and optimistic in nature. The list of the modern machinaries present in workshop are listed below along with their information.

Ovens in Prosthetics and Orthotics are used for heating and moulding materials to create

Prosthetic and Orthotic devices. Following are the three types of Ovens

mainly

used in Production of Prostheses and Orthoses :

1. Prosthetic and Orthotic Oven

2. Infrared Oven

3. Prosthetics Orthotics Industrial Oven

Essential for Shaping, Smoothing, and Finishing Orthotic Devices and Prosthetic Components. In the manufacturing of Medical Instruments, External Cylindrical Grinders are commonly used to process the external components of implantable medical devices such as Joint Prostheses and Bone Plates. They ensure precision in Dimensions and Surface Smoothness, thereby enhancing the patient's treatment experience

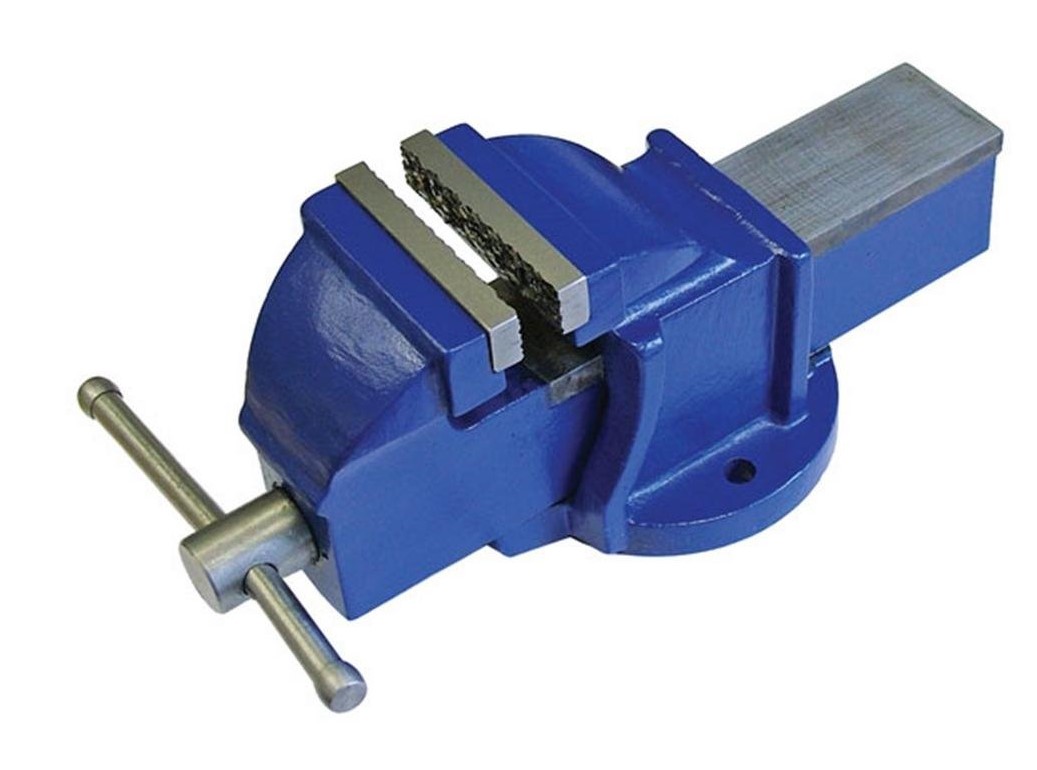

A Bench Vise is an essential and integral tool used in Metalworking, Woodworking, and some other manufacturing applications. It is mounted on workbenches and its main function is to hold the workpiece safely and securely. A Bench Vice, also known as a Workshop Vice, is a mechanical device designed to hold workpieces firmly in place while performing tasks such as Cutting, Drilling, Filing, or Soldering.

One of the main functions of Orthopedic Bone Drills is to Drill Holes in bones through a rapidly rotating drill bit. This drilling process requires high precision to ensure the accurate installation of implants (such as screws or prostheses) and effective fixation of fractures. An Ortho drill is a pneumatic or electric device that is used by an Orthopedic surgeon to make holes in bones for fixing Immobilization Screws, Wires, Plates, Implants and Fitting Prosthetic Devices etc.

The full form of AP-ML is Anterior-Posterior and Medial-Lateral :

AP: Anterior-Posterior Distance

ML: Medial-Lateral Distance

The Original AP-ML Gauge is an anatomical measuring tool from Fillauer LLC that measures in

inches and metric. It is a universal Anterior-Posterior–Medial-Lateral Caliper.

Double Click for Full View